2007

Shenzhen Light Green International Lighting Co.,Ltd was established.

2009

In 2009, The export sales of LED flat panel light exceeded 30,000 sets, becoming the largest LED flat panel light manufacturer in China.

2011

In 2011, Light Green Was named "national high-tech enterprises" in the same year green lighting as the main drafting unit participated in the "LED flat panel light performance requirements" standard development, the standard was formally implemented in 2012.

2013

In 2013, LED flat panel light in the domestic sales exceeded 300,000 sets, to maintain the LED flat panel light of the largest manufacturer in the industry, the same year, green lighting put forward the city of intelligent architectural lighting concept.

2017

In 2017, the "Shenzhen Belt and Road Economic and Technical Cooperation Association" was organized and formally reached cooperation intentions with the five countries along the Belt and Road: Kazakhstan, Bahrain, Iran, the Czech Republic, and Russia. At present, the association has hundreds of formal members, including 9 listed companies with a total market value of hundreds of billions of yuan.

2021 to present

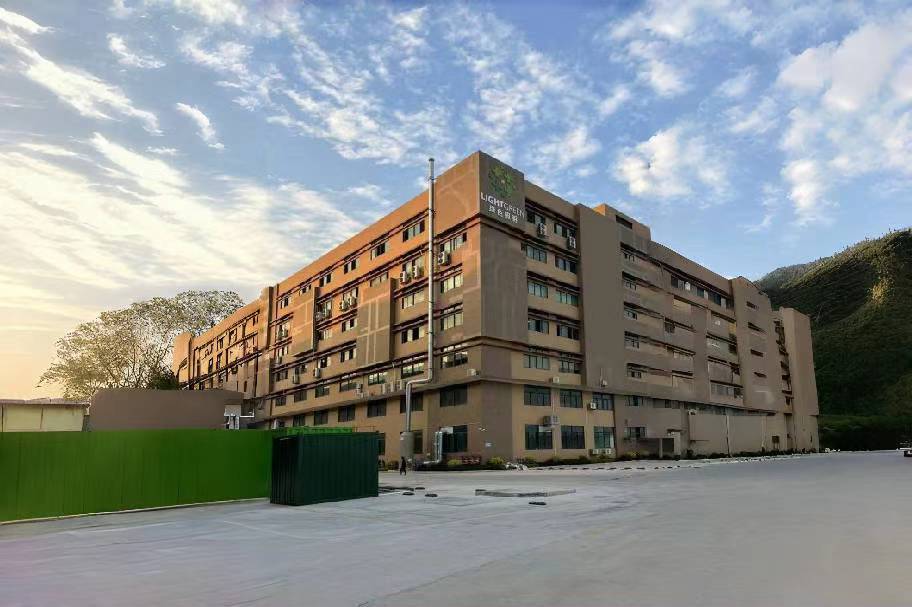

At the end of 2021, the company formally established a branch in Gangkou Town, Zhongshan City. It based on the led lights, Light Green is mainly engaged in intelligent product development and platform development.